ro filter system

Links

- 4. Multiple Compartments Many lockable metal tool boxes come with multiple compartments and shelves, allowing you to organize your tools neatly and efficiently. This not only makes it easier to find what you need but also helps prevent damage to delicate items.

- Another important factor to consider when selecting rollers for aluminum sliding windows is noise reduction. Low-quality or worn-out rollers can create squeaking or grinding noises when the window is opened or closed, which can be both annoying and disruptive. By choosing rollers that are specifically designed for noise reduction, homeowners can enjoy a quiet and peaceful indoor environment without the distraction of loud window operation sounds.

-

The production of aluminum fences is scalable to huge numbers. An aluminum fence is typically made using a manufacturing process known as extrusion. This procedure entails nothing more than moving blocks of aluminum through a dying system.

- In addition to their durability, aluminum sliding door rollers are also incredibly easy to maintain. Unlike other types of door rollers that may require frequent lubrication and adjustments, aluminum rollers are low-maintenance and can easily be cleaned with a simple wipe-down. This makes them an ideal choice for homeowners who want a hassle-free door system that requires minimal upkeep.

- Furthermore, aluminium glazing beads contribute to the sustainability of a building project. Aluminium is a highly recyclable material, which means that even at the end of their service life, these beads can be repurposed, reducing waste and environmental impact.

- In conclusion, the round bar pull handle is a testament to the power of well-designed functional objects. Its enduring popularity lies in its ability to harmoniously blend form and function, providing a subtle yet impactful touch to any interior design. Whether you're renovating your home or designing a commercial space, considering the round bar pull handle can elevate the look and feel of your project, turning simple openings into stylish statements.

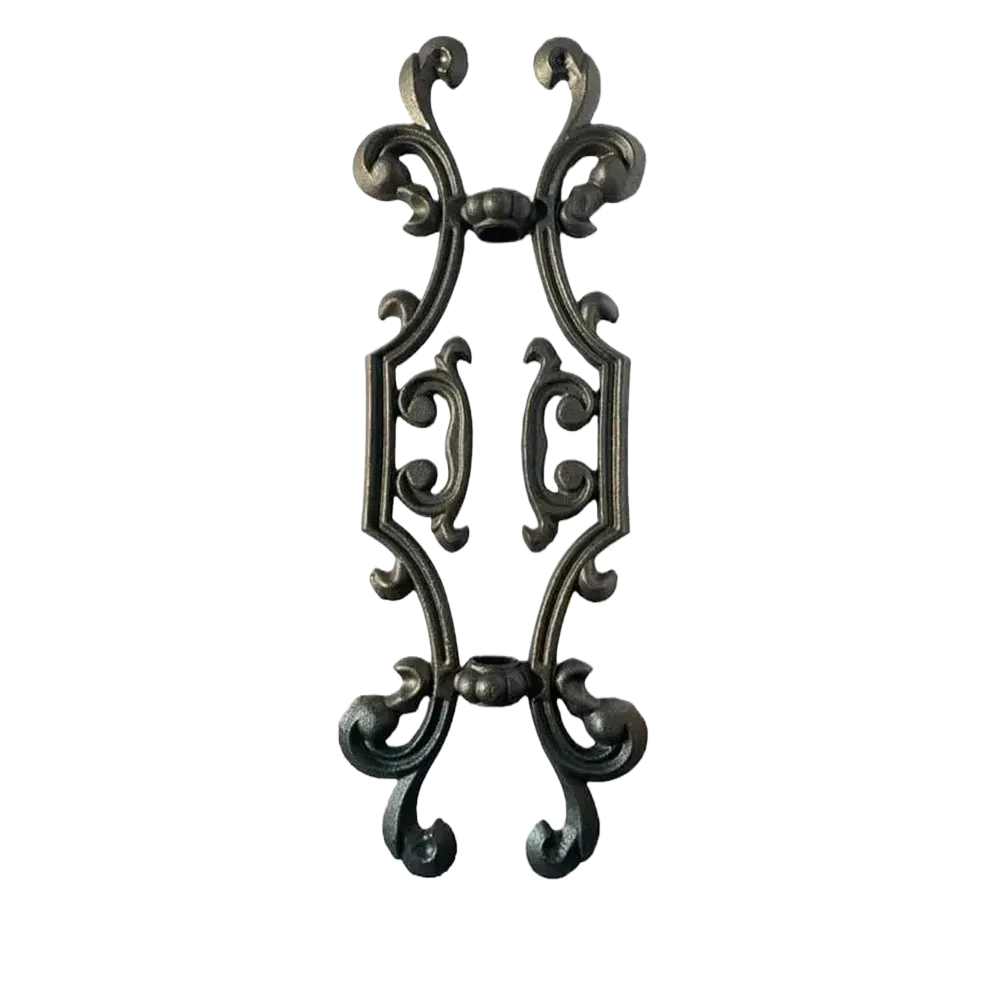

- The process of creating ornamental iron posts is a blend of art and science. It begins with the selection of high-quality iron, followed by heating and shaping using traditional forging techniques or modern CNC machines. Each post is then meticulously crafted, with every curve and angle carefully designed to harmonize with its surroundings.

-

Wrought iron is a durable material that can withstand the elements and last for years to come. This makes it an excellent choice for fencing, as it requires minimal maintenance and will continue to look beautiful for many years.

-

T3, T4, T5, T6, T7, T8 -

Cast Iron Railing Panel

-

The melted material is then poured into a mold (i.e. a “cast”) with a predetermined shape and allowed to cool. Cast iron structures can be as simple or intricate as the mold they were poured into, and the fact that the iron solidified all in one continuous piece helps make these structures extremely sturdy.

For over 40 years, Our commitment to quality materials and superlative standards of production guarantee that you’ll receive finished products of exceptional craftsmanship.

- Moreover, these wheels and tracks come together in a symphony of silence that is both calming and essential in modern homes. The absence of squeaks and creaks provides not just a physical ease of movement but also a sonic pleasure—an aspect often overlooked but profoundly impactful on our daily lives.

- In today's fast-paced world, the need to protect our valuable items has never been more crucial. From important documents and jewelry to electronic devices and cash, we all have something that we want to keep safe. That's where a steel security safe lock box comes in.

- Furthermore, a reputable wrought iron supplier will offer competitive pricing and excellent customer service. They will work closely with you to understand your requirements and budget constraints, providing you with cost-effective solutions that do not compromise on quality. Additionally, they will be responsive to your inquiries and concerns, offering support and guidance throughout the duration of your project.

- The main differences between cast iron and wrought iron are their physical properties and manufacturing processes. Wrought iron is manufactured through heating, bending, and working, while cast iron products are released into their appropriate shapes. It is nearly universally agreed that cast iron is more accessible to produce than wrought iron.

However, wrought iron is more substantial than cast iron, so it is more likely to be used in commercial applications. Conversely, cast iron is harder than wrought iron and can resist deformation under pressure or stress more quickly than wrought iron.

2. Lubricate Rollers Periodically apply a silicone-based lubricant to the rollers and tracks. Avoid using oil-based products that can attract dirt.

They contribute significantly to the overall ambiance and character of a space They contribute significantly to the overall ambiance and character of a space

They contribute significantly to the overall ambiance and character of a space They contribute significantly to the overall ambiance and character of a space door and window hardware company. A well-designed handle can elevate the look of a door, while a sturdy lock provides the much-needed security. The hardware, therefore, becomes a silent testament to the attention to detail and commitment to quality that defines a building.

door and window hardware company. A well-designed handle can elevate the look of a door, while a sturdy lock provides the much-needed security. The hardware, therefore, becomes a silent testament to the attention to detail and commitment to quality that defines a building. In this comprehensive guide, we’ll look at what makes these two materials unique and how to choose between them. From durability and design flexibility to maintenance and cost, we’ll provide you with all the information you need to make an informed decision for your fencing project.

There are two potential drawbacks to this window. One is that if it’s placed over a kitchen sink, reaching out to close the window is difficult. The second is that if it’s fitted to ground floor level or opens onto pathways, it may need restricting to avoid injury to others.

5. Ease of Installation Slimline aluminium profiles are lightweight and easy to work with, enabling faster installation. This can lead to reduced labor costs and shorter project timelines, making them a favorite among contractors. Their precision-engineered design allows for easy assembly and alignment, ensuring efficient workflow on construction sites.

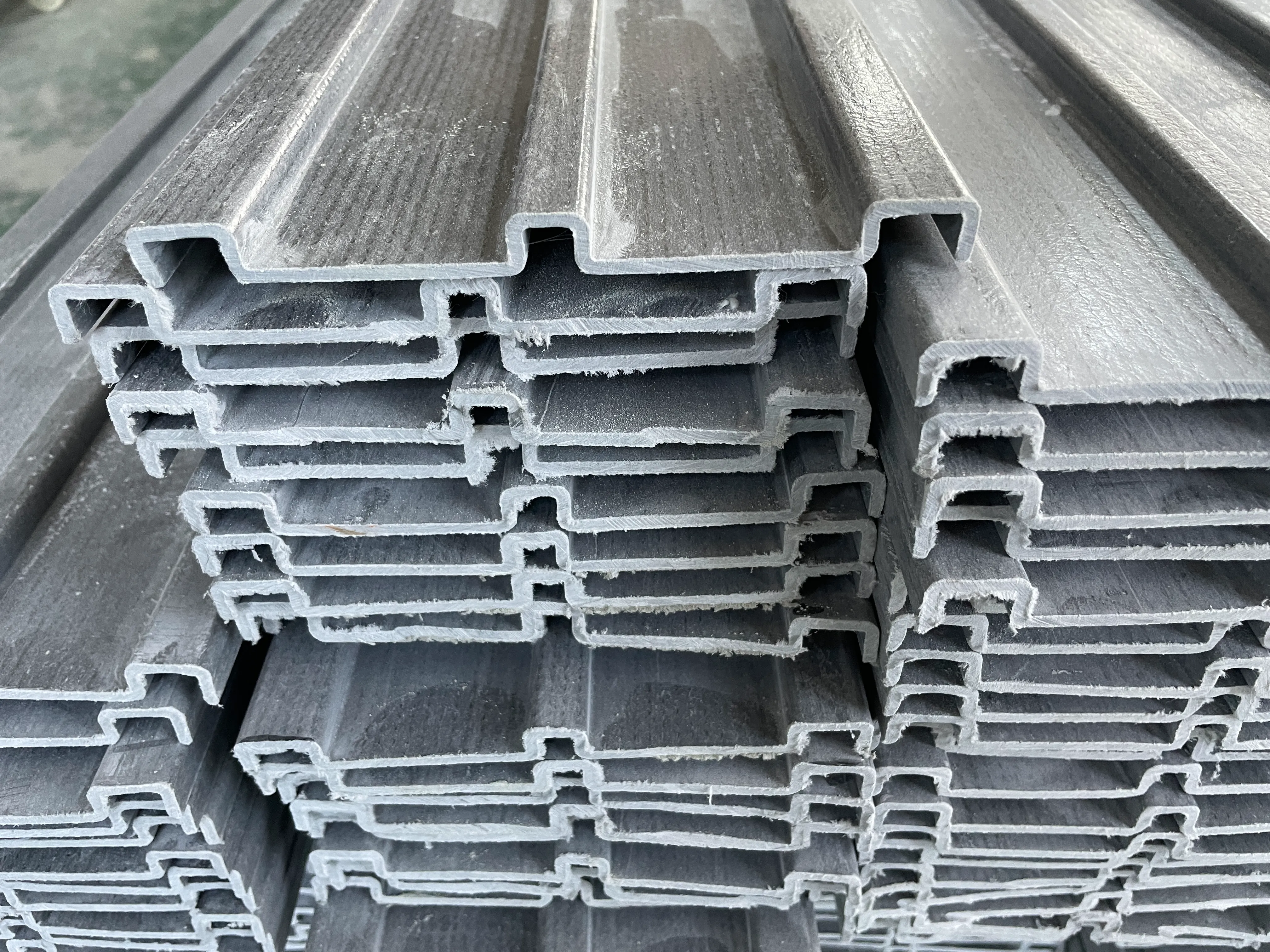

aluminum window channel extrusion. The ability to create customized profiles enables the realization of unique architectural visions, where windows can seamlessly integrate with the overall design scheme. This flexibility allows for the creation of visually stunning buildings that push the boundaries of traditional architecture.

aluminum window channel extrusion. The ability to create customized profiles enables the realization of unique architectural visions, where windows can seamlessly integrate with the overall design scheme. This flexibility allows for the creation of visually stunning buildings that push the boundaries of traditional architecture.